The AMADA HFE3i series are the latest evolution in hydraulic drive press brakes. Designed with the solid characteristics of the HFE series, the 3i series features new additions to improve productivity, as well as, a highly innovative multi-touch screen interface. The processing precision enables the production of very high quality batches, at low energy costs and with an unrivalled process stability. The extensive range of sizes (from 50 tons, 1.2 m to 400 tons, 6 m) and options mean that customers can configure the ideal bending solution for their specific needs.

DIGITAL AND CONNECTED:

Due to digital technology and innovative numerical control, the HFE3i is always connected, fully integrated with the offline programming software and “Industry 4.0” compatible.

ACCURATE:

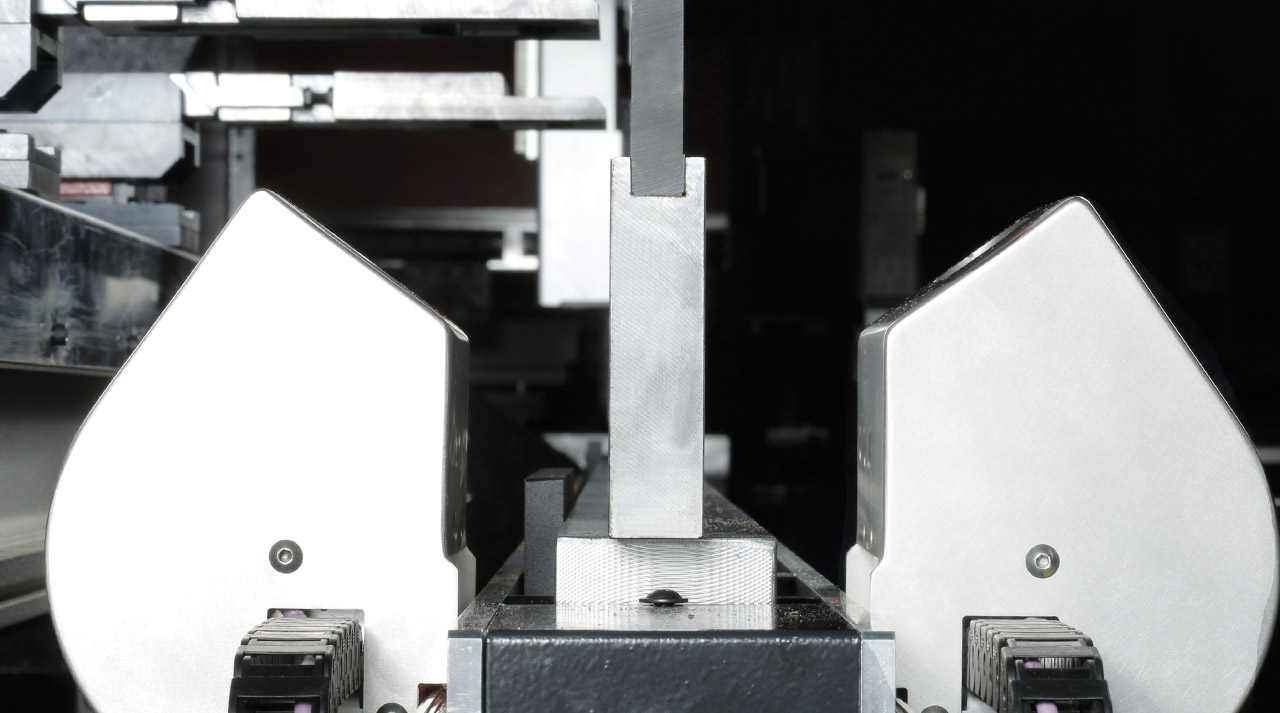

The AMADA-patented crowning system, based on the parallel deformation of the beams, guarantees constant results over the entire bend length without the need to add costly electromechanical or hydraulic systems. Moreover, the HFE3i has a number of mechanical bending indicators (Bi-S) and laser bending indicators (Bi-M), that can ensure maximum bending precision, eliminating rejected parts.

ECO-FRIENDLY:

The Eco drive system guarantees smart hydraulic system management, providing considerable benefits such as reduced power consumption, improved system performance, reliability and stability.

| HFE3i-5012 | HFE3i-5020 | HFE3i-8025 | |

|---|---|---|---|

| Press capacity (kN) | 500 | 500 | 800 |

| Press beam length (mm) | 1270 | 2090 | 2570 |

| Distance between frames (mm) | 1035 | 1665 | 2125 |

| Stroke (mm) | 150 | 200 | 200 |

| Open height without holder (mm) | 480 | 470 | 470 |

| Throat depth (mm) | 100 | 420 | 420 |

| Working height (mm) | 920 | 960 | 960 |

| Bending speed (mm/sec) | 25 | 15 | 15 |

| Approach speed (mm/sec) | 220 | 200 | 200 |

| Return speed (mm/sec) | 220 | 150 | 150 |

Dimensions: | |||

| Length (mm) | 2653 | 3575 | 4035 |

| Width (mm) | 2267 | 2660 | 2660 |

| Height (mm) | 2420 | 2440 | 2540 |

| Weight (kg) | 3550 | 4700 | 5600 |

| HFE3i-1003 | HFE3i-1303 | |

|---|---|---|

| Press capacity (kN) | 1000 | 1300 |

| Press beam length (mm) | 3110 | 3140 |

| Distance between frames (mm) | 2705 | 2700 |

| Stroke (mm) | 200 | 200 |

| Open height without holder (mm) | 470 | 470 |

| Throat depth (mm) | 420 | 420 |

| Working height (mm) | 960 | 960 |

| Bending speed (mm/sec) | 15 | 10 |

| Approach speed (mm/sec) | 200 | 100 |

| Return speed (mm/sec) | 150 | 100 |

Dimensions: | ||

| Length (mm) | 4615 | 4620 |

| Width (mm) | 2660 | 2700 |

| Height (mm) | 2680 | 2805 |

| Weight (kg) | 6600 | 8150 |

| HFE3i-1703 | HFE3i-1704 | HFE3i-17045 | |

|---|---|---|---|

| Press capacity (kN) | 1700 | 1700 | 1700 |

| Press beam length (mm) | 3170 | 4230 | 4520 |

| Distance between frames (mm) | 2700 | 3760 | 4050 |

| Stroke (mm) | 200 | 200 | 200 |

| Open height without holder (mm) | 470 | 470 | 470 |

| Throat depth (mm) | 420 | 420 | 420 |

| Working height (mm) | 960 | 960 | 960 |

| Bending speed (mm/sec) | 10 | 10 | 10 |

| Approach speed (mm/sec) | 100 | 100 | 100 |

| Return speed (mm/sec) | 100 | 100 | 100 |

Dimensions: | |||

| Length (mm) | 4650 | 5710 | 6000 |

| Width (mm) | 2763 | 2700 | 2700 |

| Height (mm) | 2880 | 2890 | 3000 |

| Weight (kg) | 11600 | 13900 | 14800 |

| HFE3i-2203 | HFE3i-2204 | |

|---|---|---|

| Press capacity (kN) | 2200 | 2200 |

| Press beam length (mm) | 3220 | 4280 |

| Distance between frames (mm) | 2700 | 3760 |

| Stroke (mm) | 200 | 200 |

| Open height without holder (mm) | 470 | 470 |

| Throat depth (mm) | 420 | 420 |

| Working height (mm) | 960 | 690 |

| Bending speed (mm/sec) | 10 | 10 |

| Approach speed (mm/sec) | 100 | 100 |

| Return speed (mm/sec) | 100 | 100 |

Dimensions: | ||

| Length (mm) | 4650 | 5740 |

| Width (mm) | 2763 | 2700 |

| Height (mm) | 3185 | 3080 |

| Weight (kg) | 13750 | 17000 |

| HFE3i-4004 | HFE3i-4005 | HFE3i-4006 | |

|---|---|---|---|

| Press capacity (kN) | 4000 | 4000 | 4000 |

| Press beam length (mm) | 4100 | 5020 | 6100 |

| Distance between frames (mm) | 3230 | 4150 | 5230 |

| Stroke (mm) | 350 | 350 | 350 |

| Open height without holder (mm) | 620 | 620 | 620 |

| Throat depth (mm) | 420 | 420 | 420 |

| Working height (mm) | 960 | 960 | 960 |

| Bending speed (mm/sec) | 10 | 10 | 10 |

| Approach speed (mm/sec) | 100 | 100 | 100 |

| Return speed (mm/sec) | 100 | 100 | 100 |

Dimensions: | |||

| Length (mm) | 5570 | 6490 | 7570 |

| Width (mm) | 3330 | 3277 | 3330 |

| Height (mm) | 3385 | 3685 | 3835 |

| Weight (kg) | 24400 | 33500 | 36000 |

Technical data can vary depending on configuration / options

Please contact us for more details and options or download our brochure

For your safe use.

Be sure to read the user manual carefully before use.

When using this product, appropriate personal protection equipment must be used.